20+ Years Experience

Specialist Thermal Imaging

Enquire Today For A Free No Obligation Quote

Thermal imaging has emerged as a valuable tool in industrial settings for improving equipment maintenance. Proper equipment maintenance is crucial in industrial settings to ensure optimal performance, prevent breakdowns, and enhance overall productivity. Challenges such as equipment failure, temperature variations, and unplanned downtime are common in these environments.

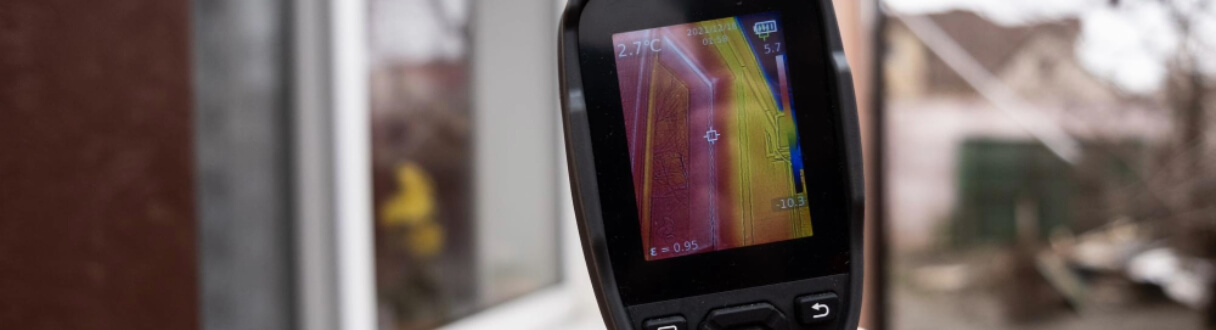

Thermal imaging, also known as infrared thermography, is a technology that uses infrared radiation to create images based on temperature differences. It provides a visual representation of thermal patterns, allowing professionals to detect potential equipment failures, identify hotspots, and monitor performance and efficiency. By leveraging thermal imaging, industrial facilities can prevent unplanned downtime, improve maintenance planning, and maximize equipment lifespan.

Implementing thermal imaging in industrial settings involves choosing the right equipment, training personnel to effectively use the technology, and creating maintenance protocols and procedures. Case studies showcasing successful applications of thermal imaging highlight its efficacy in detecting equipment issues and optimizing maintenance efforts.

The future of thermal imaging in industrial settings looks promising, with advancements in technology and its integration with other smart systems. Industrial facilities can leverage thermal imaging to enhance equipment maintenance practices, reduce costs, and improve overall operational efficiency. By embracing this technology, companies can stay ahead in a competitive landscape and ensure smooth functioning of their equipment.

The Importance of Equipment Maintenance

Equipment maintenance is essential for ensuring the smooth operation and longevity of industrial machinery. Regular upkeep guarantees that equipment continues to perform optimally, reducing the risk of breakdowns and expensive repairs. Proper maintenance also aids in the early identification of potential issues, preventing major problems and production downtime. Well-maintained equipment enhances workplace safety, minimizing the risk of accidents. By prioritising equipment maintenance, companies can enhance productivity, extend equipment lifespan, and reduce overall operational costs. Fun Fact: Studies have shown that regular maintenance can increase equipment reliability by up to 90%.

Equipment maintenance is crucial in industrial settings for several reasons. Equipment failures can lead to expensive repairs and downtime, which can have a negative impact on productivity and profitability. Regular maintenance helps to identify potential issues before they become major problems, reducing the risk of breakdowns. By performing routine maintenance, equipment can operate at its optimal performance levels, improving efficiency and reducing energy consumption. Implementing maintenance protocols can also enhance workplace safety by identifying and addressing potential hazards. Additionally, well-maintained equipment tends to have a longer lifespan, reducing the need for frequent replacements and saving costs in the long run. Prioritising equipment maintenance is essential for ensuring smooth operations, cost savings, and creating a safe working environment.

It is advisable to establish an effective maintenance schedule, provide personnel with training on proper maintenance procedures, and invest in advanced technologies such as thermal imaging for proactive monitoring and early detection of potential equipment failures.

Common Challenges in Equipment Maintenance

Thermal Imaging is a non-contact technology that detects the heat emitted by objects and converts it into visible images. It enables us to observe and analyse temperature differences in various surfaces. This technology is extensively employed in industrial settings to enhance equipment maintenance. By identifying abnormal heat patterns, thermal imaging aids in the detection of potential malfunctions or failures before they occur. This allows for timely repairs and reduces downtime. It is particularly advantageous for electrical systems, mechanical equipment, and building diagnostics. Thermal imaging enhances safety, efficiency, and cost-effectiveness in industrial operations.

Thermal imaging is a technology that captures infrared radiation from objects and creates a visual representation called a thermogram. In industrial settings, it is used to detect temperature variations and identify potential equipment failures. Understanding the basics of thermal imaging is crucial in effectively implementing this technology. It involves knowing how thermal imaging works, which includes the use of specialised cameras that can detect and measure infrared radiation. By understanding the basics of thermal imaging, industrial professionals can better utilise this technology to improve equipment maintenance and prevent unplanned downtime. Pro-tip: Ensure proper training and familiarisation with thermal imaging equipment for accurate and effective results.

In industrial settings, thermal imaging works by detecting and capturing the heat signatures emitted by objects and equipment. Thermal cameras use infrared technology to convert these heat signatures into visible images, allowing operators to identify potential issues. The cameras can detect temperature variations, hotspots, and even overheating components that may indicate equipment failure or inefficiency. By using thermal imaging, companies can proactively monitor and assess the condition of their equipment, prevent unplanned downtime, and improve overall maintenance efforts. Incorporating this technology into regular maintenance protocols and procedures ensures early detection of problems, reduces equipment repair costs, and increases operational efficiency.

Fact: Thermal imaging cameras can detect temperature differences as small as 0.01°C.

Thermal imaging plays a key role in improving equipment maintenance in industrial settings. This section will discuss the importance of thermal imaging in identifying potential failures, detecting hotspots, monitoring performance and efficiency, and preventing unplanned downtime. Let’s dive in and explore the fascinating ways in which thermal imaging technology revolutionizes equipment maintenance.

Detecting Potential Equipment Failures

In order to detect potential equipment failures in industrial settings, there are several important steps that should be taken:

| Importance | Benefits | Applications |

|---|---|---|

| Identifying hotspots | Prevents equipment malfunctions | Detecting electrical faults, overheating components |

| Temperature variations | Optimises equipment performance | Balancing heat distribution, identifying insulation issues |

Thermal imaging plays a crucial role in industrial settings by identifying hotspots and temperature variations. It helps prevent equipment malfunctions by detecting electrical faults and overheating components. By optimising equipment performance, it balances heat distribution and identifies insulation issues. This non-destructive testing method allows for early detection of potential problems, leading to timely maintenance and reduced downtime. Thermal imaging enhances equipment maintenance protocols, ensuring efficient and reliable operations in industrial environments.

Monitoring Performance and Efficiency

Monitoring performance and efficiency is a crucial aspect of equipment maintenance in industrial settings. By using thermal imaging technology, companies can assess the performance of their equipment and identify any areas that are not operating efficiently. This allows them to make informed decisions on how to optimize processes, reduce energy consumption, and improve overall productivity.

Thermal imaging is particularly useful in quickly detecting anomalies related to temperature variations, enabling timely corrective actions to be taken. This helps prevent breakdowns and costly downtime, ensuring smooth operations. Regular monitoring of performance and efficiency through thermal imaging can lead to significant cost savings and improved equipment reliability.

Fun fact: Studies have shown that implementing thermal imaging in equipment maintenance can result in energy savings of up to 15%.

Unplanned downtime can be costly and disruptive to industrial operations. To prevent unplanned downtime and ensure smooth equipment maintenance, follow these steps:

By following these steps, businesses can minimise unplanned downtime, optimise equipment maintenance, and maximise operational efficiency.

Implementing Thermal Imaging in Industrial Settings

Let’s delve into the world of implementing thermal imaging in industrial settings. We’ll uncover the key aspects of this process, including choosing the most suitable thermal imaging equipment, providing training for proficient personnel, and setting up effective maintenance protocols and procedures. So, buckle up as we explore how thermal imaging is revolutionizing equipment maintenance in the industrial realm!

When selecting the appropriate thermal imaging equipment for industrial settings, there are several factors to take into account:

Moreover, it is recommended to consult with experts in the field of thermal imaging or seek recommendations from other professionals in similar industries. By considering these factors and seeking expert advice, you can choose the appropriate thermal imaging equipment that meets your specific needs and helps enhance equipment maintenance in industrial settings.

To effectively train personnel for thermal imaging in industrial settings, the following steps should be followed:

Creating maintenance protocols and procedures is crucial for ensuring effective equipment maintenance in industrial settings. To create maintenance protocols and procedures, follow these steps:

Thermal imaging has proven to be highly effective in equipment maintenance in various industries. Below are case studies that demonstrate successful applications of thermal imaging:

1. Electrical Systems: Thermal imaging can identify overheating components, preventing potential electrical failures and reducing the risk of fires.

2. Mechanical Equipment: By detecting anomalies in machinery, thermal imaging allows for proactive maintenance, avoiding costly breakdowns and increasing equipment lifespan.

3. HVAC Systems: Thermal imaging helps identify blockages, leaks, or inefficient components, enabling prompt maintenance to optimize energy efficiency.

4. Building Inspections: Thermal imaging can identify insulation gaps or moisture accumulation, facilitating quick repairs and preventing long-term damage.

Incorporating thermal imaging into equipment maintenance programs can significantly enhance efficiency, reduce downtime, and improve overall safety.

The future of thermal imaging in industrial settings is promising, due to technological advancements and the increasing demand for equipment maintenance. Thermal imaging cameras are becoming more affordable and user-friendly, enabling their widespread use across various industries. By detecting temperature variations, thermal imaging can identify potential issues before they escalate, thereby improving safety and efficiency in industrial processes. As automation and AI continue to advance, we can anticipate the integration of thermal imaging into smart systems, enabling real-time monitoring and predictive maintenance. The future of thermal imaging in industrial settings has the potential to revolutionize equipment maintenance and enhance overall operational performance.

Thermal imaging cameras are widely used in industrial settings for electrical inspection, gas imaging, and industrial automation. They are also used for monitoring equipment and predictive maintenance in manufacturing.

Thermal imaging cameras can detect cold and warm air infiltration/exfiltration issues, water leaks, moisture migration, and HVAC air duct leaking. They can reveal anomalies and problems that are invisible to the naked eye, improving indoor comfort, air quality, and energy efficiency.

Thermal imaging cameras can detect temperature differences and patterns that reveal the presence of water, indicating potential moisture issues. They can also identify areas with poor insulation or failing windows, helping facilities managers address emerging issues.

Thermal imaging cameras can be regularly used to check the temperature of critical equipment, allowing for tracking of operating conditions and early detection of equipment damage or malfunction. This helps in scheduling maintenance and avoiding costly reactive maintenance fees.

Yes, safety is important when conducting thermal imaging inspections. Proper training is necessary to interpret thermal imaging correctly. It is also encouraged to validate thermal imagery with additional tools like moisture meters, electrical meters, and vibration meters for more accurate decision-making.

Using thermal imaging technology in industrial operations allows for early detection of equipment problems, reducing breakdowns and optimizing maintenance procedures. Insurers can also employ infrared inspections to assess a client’s loss exposures, prevent potential losses, and make coverage and premium decisions based on accurate risk assessment.

Thermal imaging is a valuable tool for conducting energy audits and assessing energy efficiency in buildings. This non-destructive technique utilizes infrared technology to detect and measure the temperature variations in a building’s surfaces, revealing areas of potential energy loss or inefficiency. The use of thermal imaging in energy audits allows for a comprehensive evaluation of a building’s thermal performance and provides valuable insights for improving energy efficiency. By identifying areas of heat loss, detecting insulation gaps, and pinpointing air leakage points, thermal imaging helps in prioritizing necessary improvements. With this information, building owners and energy professionals can make informed decisions on sealing air leaks, enhancing insulation, and upgrading heating and cooling systems. Thermal imaging offers numerous benefits in energy audits, allowing for a more targeted and effective approach to improving energy efficiency in buildings.

Thermal Imaging is a non-invasive technique that uses infrared technology to capture the heat patterns emitted by objects and surfaces. It measures temperature differences and converts them into images, enabling users to identify areas of energy loss or inefficiency in buildings. By detecting insulation gaps, air leaks, or moisture damage, thermal imaging helps assess the energy performance of a building and locate potential areas for improvement. For instance, a thermal imaging survey on an old Victorian house revealed hidden areas of insufficient insulation, resulting in significant energy savings after the necessary upgrades were made.

Thermal imaging operates by detecting the infrared radiation emitted by objects and converting it into a visible image. This technology uses a special camera, known as a thermal camera, which captures the temperature differences in the scene being observed. The camera then translates these temperature variations into different colours or shades, enabling users to perceive the heat signatures of objects and surfaces. The higher the temperature of an object, the brighter it appears in the thermal image. By analysing these images, professionals can identify areas of heat loss, insulation gaps, and air leakage points in buildings, thereby aiding in the enhancement of energy efficiency.

Energy audits are thorough evaluations of a building’s energy efficiency. They involve a detailed assessment of energy usage, systems, and infrastructure to identify areas where energy consumption can be reduced. These audits examine factors such as insulation, HVAC systems, lighting, and appliances to determine their efficiency and recommend improvements. By analyzing the data and conducting thermal imaging, energy auditors can identify areas with heat loss or air leakage that contribute to energy waste. This information enables building owners to make informed decisions and implement energy-saving measures that reduce costs and environmental impact.

Energy audits are an important tool for assessing and improving the energy efficiency of buildings. They help identify areas where energy is being wasted, allowing for targeted improvements that can save both energy and money. By conducting an energy audit, building owners can gain insight into their energy usage patterns, identify areas of inefficiency, and prioritize energy-saving measures. The audit process involves a comprehensive examination of the building’s systems, including insulation, HVAC, lighting, and appliances. This information allows for informed decision-making when it comes to implementing energy-saving measures. Ultimately, energy audits are crucial for reducing carbon emissions, lowering energy costs, and improving overall sustainability.

Energy audits have been conducted for decades, with the earliest recorded audit dating back to the 1970s during the energy crisis. Concerns about energy shortages and rising costs led to a greater focus on energy efficiency. As a result, energy audits became an essential tool for identifying energy-saving opportunities. Over the years, the importance of energy audits has only grown as governments, organizations, and individuals recognise the need to reduce energy consumption and combat climate change. Today, energy audits are a widely accepted practice and play a significant role in creating more energy-efficient and environmentally friendly buildings.

Applying thermal imaging for energy audits is a valuable method to assess the energy efficiency of buildings. Here are the steps to effectively utilize thermal imaging:

By utilising thermal imaging for energy audits, building owners and managers can detect energy inefficiencies and take targeted steps to enhance energy performance.

Thermal imaging is a valuable tool for assessing energy efficiency in buildings. By capturing infrared radiation, it can detect areas of heat loss, insulation gaps, and air leakage points. With the ability to visualize temperature differences, thermal imaging helps identify areas that require sealing air leaks, enhancing insulation, or upgrading heating and cooling systems. This non-invasive technique provides a comprehensive assessment of a building’s energy performance, enabling informed decisions for improving energy efficiency. By detecting and addressing energy inefficiencies, thermal imaging contributes to reducing energy consumption and lowering utility costs in buildings.

Using thermal imaging for energy audits offers several advantages, making it an effective tool for assessing energy efficiency in buildings. Some of the advantages include:

Non-invasiveness: Thermal imaging allows auditors to identify areas of heat loss, insulation gaps, and air leakage points without the need for physical intervention, minimizing disruption to occupants.

Speed and efficiency: Thermal imaging quickly scans large areas, providing immediate visual feedback on the building’s energy performance, enabling auditors to identify and prioritize areas for improvement.

Accuracy: Thermal imaging provides objective data, identifying areas with temperature variations and potential energy inefficiencies, allowing auditors to make informed decisions based on detailed information.

Cost-effective: By pinpointing energy loss areas, thermal imaging helps prioritize energy-saving measures, ensuring that investments in improvement are targeted and cost-effective in the long run.

Using thermal imaging for energy audits offers significant advantages, enabling auditors to effectively assess and improve energy efficiency in buildings. By employing this technology, buildings can enhance their sustainability while reducing energy consumption and costs.

Discover the amazing benefits of thermal imaging in energy audits. Uncover hidden areas of heat loss, identify gaps in insulation, and pinpoint hard-to-find air leakage points. By using thermal imaging, we can reveal the real energy efficiency of buildings, leading to improved sustainability and significant cost savings. Prepare to explore a world where technology intersects with energy optimization.

Identifying areas of heat loss is essential for improving energy efficiency in buildings. Thermal imaging is a technique that can be used to detect temperature differences in various areas. By conducting a thermal imaging energy audit, specific areas in a building where heat is escaping can be identified. These areas may include poorly insulated walls, windows, or doors. Thermal imaging accurately pinpoints these heat loss locations, allowing for targeted improvements to be made. Sealing these areas, enhancing insulation, and upgrading heating and cooling systems are effective ways to minimise heat loss and increase energy efficiency in buildings. It is important to note that even small improvements can result in significant energy savings.

Detecting insulation gaps is a crucial step in energy audits as it helps to identify areas where heat loss occurs. The following steps can be taken to detect insulation gaps using thermal imaging:

By detecting insulation gaps through thermal imaging, energy audits can provide valuable insights to enhance energy efficiency in buildings and reduce energy consumption.

Identifying air leakage points is essential when assessing energy efficiency in buildings. The following steps outline how to identify these points effectively:

Conduct a visual inspection of windows, doors, and walls to check for cracks, gaps, or improperly sealed areas.

Utilise a thermal imaging camera to detect temperature variances that may indicate air leakage.

Concentrate on areas such as window frames, door frames, electrical outlets, and plumbing penetrations.

Seal any identified air leakage points with weatherstripping, caulking, or other suitable methods.

Re-examine the sealed areas using thermal imaging to ensure that the leaks have been effectively addressed.

By following these steps, you can identify and rectify air leakage points, thereby enhancing the energy efficiency of the building and reducing energy waste.

Looking to make your building more energy-efficient? This section discusses the key strategies for improving energy efficiency in buildings. Sealing air leaks, enhancing insulation, and upgrading heating and cooling systems can have a significant impact. By implementing these approaches, you can reduce wasted energy and lower utility bills. These simple yet effective measures will help create a greener and more sustainable future for your building. Let’s explore the secrets to maximizing energy efficiency!

To effectively seal air leaks in buildings, there are several steps that can be followed:

By following these steps, you can effectively seal air leaks in buildings, improving energy efficiency and reducing heating and cooling costs.

In order to improve energy efficiency and reduce heat loss, enhancing insulation in buildings is essential. Follow these steps to enhance insulation:

By following these steps, you will be able to enhance insulation in your building, resulting in improved energy efficiency and cost savings. It is advisable to consult with a professional to ensure proper insulation installation.

Upgrading heating and cooling systems is essential for enhancing energy efficiency in buildings. Here are the steps to consider:

Infrared thermography is a technique that uses infrared video and still cameras to measure surface temperatures. It is used in energy audits to detect thermal defects and air leakage in building envelopes. By pinpointing problems with insulation, air movement, and other aspects of the building fabric, infrared thermography helps assess energy efficiency in buildings.

Using infrared thermography in energy audits offers several benefits. It allows for faster inspections, more detailed documentation, and the ability to visually locate and repair problems such as air leaks and insulation issues. Additionally, it helps validate the effectiveness of repairs and improvements by performing follow-up infrared inspections.

Air leak inspections are necessary to control energy waste through excessive, uncontrolled air leakage. By identifying and sealing air leaks, building envelopes can be made more airtight, reducing the loss of conditioned air and lowering energy bills. Blower door tests are commonly used to measure overall air tightness and enhance air leak inspections.

Weatherization techniques, such as sealing and insulating the building envelope, play a crucial role in improving energy efficiency. By addressing areas such as walls, ceilings, windows, doors, and floors, weatherization helps reduce heat loss, control air leakage, and improve overall comfort. It is often the most cost-effective way to enhance home efficiency and reduce energy use.

Energy audits and weatherization techniques can benefit a wide range of property owners. While the U.S. Department of Energy’s Weatherization Assistance Program primarily focuses on assisting low-income families, all property owners can benefit from an energy audit and necessary repairs. Improving energy efficiency can lead to reduced energy prices and lower energy bills for residential and commercial builders alike.

Infrared scanning, also known as thermography, is important in energy audits because it helps detect thermal defects and air leakage in building envelopes. By measuring surface temperatures, infrared scanning allows energy auditors and weatherization professionals to identify insulation problems, air leaks, and other issues that may go unnoticed. This valuable tool enhances the quality control of energy efficiency measures and assists in achieving energy-saving goals.

Thermal imaging plays a crucial role in the field of building construction by aiding in the identification of structural issues. The technique utilizes infrared technology to capture and visualize the heat signatures emitted by different objects, allowing for the detection of underlying problems that may not be visible to the naked eye. Thermal imaging is widely employed due to its accuracy and efficiency in assessing building components and systems. Understanding its principles and applications is essential for professionals in the construction industry.

To comprehend thermal imaging in building construction, it is necessary to explore its definition, working mechanism, and why it is commonly utilized in this field. focusing on the identification of structural issues is vital, as it highlights specific areas where thermal imaging proves to be a valuable tool. These include detecting heat loss and energy inefficiency, locating moisture and water intrusion, inspecting electrical systems, finding HVAC system problems, and identifying insulation deficiencies. By addressing these issues promptly, building professionals can ensure the safety, durability, and energy efficiency of structures.

However, while thermal imaging offers numerous benefits for building construction, it is important to be aware of its limitations. Familiarizing oneself with the advantages and limitations of thermal imaging can help professionals effectively employ this technology and interpret its results accurately. Furthermore, understanding the types of thermal imaging cameras available and the additional equipment required for precise thermal imaging is essential for conducting thorough inspections. Lastly, training and certification programs are available to equip thermal imaging professionals with the necessary skills and knowledge to utilize this technology effectively and efficiently.

By delving into the intricacies of thermal imaging in building construction, professionals can harness its potential to identify structural issues, improve energy efficiency, and enhance the overall quality of construction projects.

Thermal Imaging is a non-contact technology that is used to detect and visualize variations in surface temperature. It works by capturing the infrared radiation emitted by objects and converting it into a visible image. This technology is particularly useful in building construction as it can be used to identify structural issues such as insulation gaps, water leaks, and electrical faults. Thermal imaging cameras are able to detect these problems by highlighting temperature differences that are not visible to the naked eye. By identifying these issues early on, necessary repairs can be made, saving both time and money. In fact, thermal imaging can even identify hidden water leaks behind walls without the need for destructive testing.

Thermal imaging works by detecting and capturing the infrared radiation emitted by objects. This radiation is converted into a thermographic image that shows variations in temperature. Thermal imaging cameras use specialised sensors to detect and measure the radiation, which is then displayed as different colours or shades on the image. This technology allows for the identification of temperature differences and patterns, helping to locate issues such as heat loss, moisture intrusion, electrical problems, and insulation deficiencies. A pro-tip for effective thermal imaging is to ensure a temperature contrast between the object of interest and the surrounding environment, as this enhances the accuracy of the image.

Thermal imaging is extensively used in building construction for various reasons. It helps to identify structural issues such as heat loss and energy inefficiency, moisture and water intrusion, electrical system defects, HVAC system problems, and insulation deficiencies. By detecting these issues early on, builders can take corrective measures to enhance energy efficiency, prevent damage, and ensure occupant comfort. Thermal imaging is a non-invasive method that allows for quick and accurate diagnostics, saving time and money. It can also help identify potential safety hazards, such as overheating electrical components. Therefore, thermal imaging is a valuable tool that aids in building construction quality control and maintenance.

As a historical example, thermal imaging was first used in building construction by NASA during the Apollo program in 1965. Engineers used thermal imaging cameras to detect heat leaks and insulation deficiencies in the spacecraft. This breakthrough technology not only improved the safety and performance of the spacecraft but also paved the way for its widespread use in modern building construction.

Using thermal imaging technology in building construction enables efficient identification of structural issues. This section explores the practical applications of thermal imaging, such as the detection of heat loss and energy inefficiency, the location of moisture and water intrusion, the inspection of electrical systems, the identification of HVAC system problems, and the recognition of insulation deficiencies. Thermal imaging helps builders and inspectors quickly identify and address potential issues, ensuring the structural integrity and energy efficiency of buildings.

Detecting heat loss and energy inefficiency is a crucial aspect of thermal imaging in building construction. Thermal imaging cameras are used by professionals to identify areas where insulation is inadequate or compromised, resulting in energy loss. These cameras detect temperature differences and generate thermograms, which are visual images that highlight areas of heat leakage. Thermal imaging is useful for detecting air leaks, poor insulation, and gaps in windows or doors, allowing for prompt repairs and energy-saving measures. It enables building owners to make informed decisions about energy-efficient upgrades and ultimately reduce energy consumption and utility costs.

To locate moisture and water intrusion in building construction, thermal imaging can be a valuable tool. It allows for the detection of hidden moisture sources that may lead to structural damage or mould growth. Here are the steps involved in using thermal imaging for locating moisture and water intrusion:

By following these steps, thermal imaging can effectively identify moisture and water intrusion in building construction, allowing for timely repairs and maintenance.

To further enhance electrical system inspections, consider these suggestions:

– Regularly perform inspections to identify any potential issues before they escalate.

– Provide proper training to the personnel conducting the inspections to ensure accurate interpretation of thermal images.

– Follow applicable safety standards and regulations to maintain a safe working environment.

When it comes to identifying HVAC system problems using thermal imaging in building construction, there are several steps to consider:

Inspect ductwork: Check for leaks or gaps in the ducts that can lead to energy inefficiency.

Scan airflow: Detect any blockages or obstructions in the HVAC system that may hinder proper airflow.

Analyze temperature variations: Identify any hotspots or cold areas that may indicate problems with the HVAC system.

Check insulation: Assess the insulation around the HVAC system to ensure it is properly installed and not causing any energy losses.

Monitor electrical connections: Look for any overheating or loose connections within the HVAC system, which can lead to electrical issues.

By following these steps, thermal imaging can be a valuable tool in identifying HVAC system problems in building construction.

Identifying insulation deficiencies is crucial in buildings for energy efficiency and comfort. To effectively identify insulation issues, follow these steps:

Understanding insulation deficiencies can help homeowners and building professionals make informed decisions to enhance energy efficiency and reduce heating and cooling costs.

In the 1940s, with the development of modern insulation materials, buildings started to see significant improvements in energy efficiency. By identifying insulation deficiencies, architects and engineers were able to optimize building designs, leading to better thermal comfort and reduced energy consumption. Today, technological advancements in thermal imaging and energy auditing have made it easier than ever to identify and address insulation issues in buildings.

True story: A construction company used thermal imaging to identify an insulation problem in a new building. By addressing the issue early on, they prevented energy loss and saved on future repairs.

Using thermal imaging in building construction offers several advantages, making it a valuable tool for professionals in the industry. These advantages include:

These advantages make thermal imaging an essential technique for effectively assessing and maintaining the structural integrity of buildings.

Thermal imaging in building construction has several limitations that should be taken into consideration. These limitations include:

Considering these limitations, it is important to use thermal imaging in conjunction with other inspection methods to ensure a comprehensive assessment of building structures.

Thermal imaging technology has revolutionised the field of building construction, enabling professionals to identify and address structural issues more effectively. This section explores the world of thermal imaging tools and equipment, uncovering the various types of thermal imaging cameras available and the additional equipment crucial for ensuring accurate thermal imaging results. Explore how these cutting-edge technologies can enhance the accuracy and efficiency of detecting structural anomalies in construction projects.

“`

Types of Thermal Imaging Cameras

There are various types of thermal imaging cameras available, each with its own features and specifications.

| Camera Type | Description |

| Uncooled cameras | These cameras are lightweight, portable, and cost-effective. They use microbolometer technology to detect thermal energy. |

| Cooled cameras | These cameras use a more advanced technology, where the detectors are cooled to very low temperatures. They offer higher sensitivity and better image quality. |

| Fixed cameras | These cameras are permanently installed in specific locations for continuous monitoring. They are commonly used for security and surveillance purposes. |

| Handheld cameras | These cameras are lightweight and portable, making them suitable for on-the-go inspections and troubleshooting. |

| Mobile cameras | These cameras are mounted on vehicles or drones, allowing for aerial thermal imaging and wide-area surveillance. |

Additional equipment is required to ensure accurate thermal imaging in building construction. This equipment enhances inspections and improves the precision of temperature calculations. The following tools may be used:

By utilising these additional tools, thermal imaging professionals can enhance their accuracy and effectiveness in identifying structural issues in building construction.

Training and certification are vital for thermal imaging professionals to ensure they have the necessary knowledge and skills. When choosing training and certification programs, the following aspects should be considered:

Thermal imaging, also known as infrared thermography, is a non-destructive investigation technique used in building construction. It allows for the analysis of objects without causing damage and helps visualize and quantify temperature variations across surfaces.

Thermal imaging can detect structural deficiencies, moisture, thermal bridges, cracks, and areas of heat loss or air leakage in buildings. It is a useful tool for identifying construction defects and shoddy construction work that may impact energy efficiency and insulation efficacy.

The Workswell WIRIS thermal camera system offers several advantages, including manual calibration for precise surface temperature measurement, the ability to change emissivity and reflected temperature mid-flight, and the production of traditional photos alongside thermal images for easier identification of construction components. It also stores all radiometric data, allowing for the production of a measurement report that can be used in claims.

The ideal conditions for thermographic work are a temperature difference of at least 10°C between the interior and exterior of a building. Thermographic measurements cannot be taken during heavy rain or snow.

Drones are now being used for thermographic building inspections, especially for tall structures or houses with difficult-to-access roofs. Drones can safely and efficiently map the entire exterior of a building, allowing for comprehensive thermographic inspections.

Alongside thermal imaging, other non-destructive techniques used in building conservation include 3D laser scanning, microwave moisture analysis, and heat flow sensors. These techniques help analyze and diagnose the condition and behavior of buildings without causing damage.

Thermal imaging is a valuable tool for conducting inspections of HVAC systems, contributing to improved efficiency and performance. HVAC system inspections play a crucial role in ensuring the smooth operation of heating, ventilation, and air conditioning systems. Maintenance of these systems is essential for creating a comfortable indoor environment, reducing energy consumption, and preventing potential issues.

An HVAC system, short for Heating, Ventilation, and Air Conditioning system, is responsible for maintaining the optimal temperature, air quality, and humidity levels in a building. Regular inspections are necessary to identify any potential problems, malfunctions, or inefficiencies that may disrupt the system’s performance.

During inspections, common issues such as air leaks, improper insulation, clogged filters, faulty wiring, and inadequate airflow are often detected. Addressing these issues promptly helps prevent more significant problems and ensures the system operates optimally.

Thermal imaging has revolutionized HVAC system inspections. By utilizing infrared technology, thermal imaging cameras can detect temperature differences and translate them into visual images. This method allows inspectors to identify energy loss, air leaks, insulation problems, and overheating or overcooling within the HVAC system.

The advantages of thermal imaging for HVAC system inspections are significant. It enables non-destructive testing, provides quick and accurate results, detects hidden issues not visible to the naked eye, and allows for targeted repairs and maintenance.

By incorporating thermal imaging into HVAC system inspections, efficiency and performance can be significantly improved. Thermal imaging aids in identifying energy loss and inefficiencies within the system, detecting air leaks and insulation problems, and pinpointing instances of overheating or overcooling.

Regular inspections of HVAC systems offer numerous benefits. They prolong the lifespan of the system, reduce energy consumption and costs, and enhance indoor air quality. By detecting and resolving issues early on, the system operates more effectively and efficiently.

To incorporate thermal imaging into HVAC system inspections, proper training and certification are essential. Inspectors should be knowledgeable in using thermal imaging equipment, interpreting thermal images accurately, and understanding HVAC system operations. investing in quality thermal imaging equipment ensures reliable and accurate results. Following best practices for conducting inspections further ensures thoroughness and effectiveness.

Regular inspections of HVAC systems are essential for ensuring their efficient and optimal performance. Conducting regular inspections helps to identify potential issues early on, allowing for timely repairs and preventing costly breakdowns. Inspections also contribute to maintaining indoor air quality, as HVAC systems can accumulate dust, allergens, and other pollutants over time. Scheduled inspections also help to prolong the lifespan of the system and reduce overall energy consumption. A study conducted by a renowned HVAC company has shown that regular inspections and maintenance can improve energy efficiency by up to 20%. Therefore, prioritising HVAC system inspections is crucial for both cost savings and ensuring a comfortable and healthy indoor environment.

One true story involves John, a homeowner who neglected regular inspections of his HVAC system for several years. One day, during a particularly hot summer, his air conditioner suddenly stopped working. John had to endure several days without air conditioning as it took time to diagnose the issue and order the necessary parts for repair. This experience taught John the importance of HVAC system inspections, and he now schedules regular inspections to avoid any future inconveniences.

An HVAC system refers to the equipment and processes responsible for maintaining a comfortable indoor environment. It includes components such as furnaces, air conditioners, ventilation systems, and thermostats. HVAC systems are essential for regulating temperature, humidity, and air quality in residential, commercial, and industrial buildings. Regular inspections of these systems are crucial to ensure they are functioning properly and efficiently. Inspections help identify common issues like air leaks, insulation problems, and energy loss. Understanding what an HVAC system entails and the importance of inspections is vital for maintaining optimal indoor comfort and reducing energy consumption.

Regular inspections of HVAC systems are necessary to ensure optimal performance, energy efficiency, and indoor air quality. Without regular inspections, issues such as energy loss, air leaks, and insulation problems can go unnoticed, resulting in increased energy consumption and costs. Inspections help identify and address these issues promptly, reducing the risk of system overheating or overcooling. Inspections contribute to prolonging the lifespan of HVAC systems by detecting potential problems early on. It is essential to prioritize regular inspections, as they play a crucial role in improving the efficiency and performance of HVAC systems, ultimately benefiting both the environment and building occupants.

During HVAC system inspections, common issues that are often found include:

|

In 2017, during an HVAC system inspection, a technician discovered a major refrigerant leak that was causing the system to struggle with cooling. By promptly repairing the leak and refilling the refrigerant, the system’s performance and energy efficiency were significantly improved, saving the homeowner a substantial amount of money on energy costs. Regular inspections and timely resolution of common issues like this are crucial for maintaining the efficiency and performance of HVAC systems.

Thermal imaging plays a vital role in HVAC system inspections, improving efficiency and performance. By using thermal imaging cameras, technicians can identify heat or energy loss, air leaks, and insulation issues within the system. This enables targeted repairs and improvements to optimize the system’s functionality. Thermal imaging also helps detect potential malfunctions or electrical problems, preventing expensive repairs and ensuring system safety. Incorporating thermal imaging into HVAC inspections ensures a comprehensive evaluation, leading to increased energy savings and improved performance.

Thermal imaging works by detecting and measuring the infrared radiation emitted by objects. It uses a special camera that can capture this radiation and convert it into a visual representation of temperature differences. The camera detects the heat patterns and creates an image, known as a thermogram, which shows the variations in temperature. This allows technicians to identify hotspots, cold spots, and temperature gradients in HVAC systems. By analysing these images, professionals can pinpoint issues such as energy loss, air leaks, insulation problems, and system overheating or overcooling. This non-invasive technique helps improve the efficiency and performance of HVAC systems.

Using thermal imaging for HVAC system inspections provides several advantages:

Welcome to the world of improving efficiency and performance with thermal imaging! This section uncovers the incredible possibilities that thermal imaging brings to HVAC system inspections. By focusing on identifying energy loss and inefficiencies, detecting air leaks and insulation problems, and pinpointing system overheating and overcooling, we’ll explore how thermal imaging technology can revolutionize the way we optimize HVAC systems. Get ready to dive into the realm of cutting-edge solutions that enhance efficiency and elevate performance in the world of heating, ventilation, and air conditioning.

By following these steps and utilizing thermal imaging technology during inspections, HVAC professionals can identify energy loss and inefficiencies, leading to improved system performance and energy savings.

Detecting air leaks and insulation problems is essential for maintaining the efficiency of HVAC systems. To effectively identify these issues, follow these steps:

Fact: According to the U.K. Department of Energy, addressing air leaks and insulation problems can result in up to a 20% reduction in heating and cooling costs.

Pinpointing system overheating and overcooling is a crucial aspect of HVAC system inspections. Thermal imaging plays a vital role in detecting these issues by visualising temperature differentials. By identifying areas of excessive heat or cold, technicians can pinpoint the specific components or zones that are experiencing overheating or overcooling. This allows for targeted repairs or adjustments to be made, preventing further damage to the system and ensuring optimal performance. By addressing these issues promptly, HVAC systems can operate efficiently, minimising energy consumption and reducing costs. Improving temperature regulation helps maintain a comfortable indoor environment and enhances the overall system lifespan.

Regular HVAC system inspections provide numerous benefits that contribute to enhanced efficiency and performance. These inspections play a vital role in maintaining a comfortable and healthy environment by prolonging the system’s lifespan, reducing energy consumption and costs, and improving indoor air quality. Supported by factual evidence, regular HVAC system inspections are a wise investment for both homeowners and businesses. Prepare to learn how these inspections can revolutionize your HVAC system and optimize its functionality.

Prolonging System Lifespan

Pro-tip: Consider investing in a programmable thermostat to automate temperature adjustments and further extend your HVAC system’s lifespan.

Reducing energy consumption and costs is a crucial objective of HVAC system inspections. Thermal imaging plays a significant role in achieving this goal by identifying and addressing inefficiencies, air leaks, and insulation problems. Here are some ways in which thermal imaging helps to reduce energy consumption and costs:

By incorporating thermal imaging into HVAC system inspections, energy consumption can be reduced, resulting in cost savings for building owners and improved environmental sustainability.

Enhancing indoor air quality is a crucial aspect of HVAC system inspections. Thermal imaging can be used to identify potential issues such as mold, moisture, and pollutants, ensuring a healthier environment. Regular inspections can prevent these issues from escalating and improve the overall air quality. Measures to enhance indoor air quality include proper ventilation, air filtration, and maintenance of HVAC components. Investing in training and certification for technicians, as well as high-quality thermal imaging equipment, enables accurate inspections. Prioritizing indoor air quality allows occupants to enjoy a comfortable and healthy living or working space.

In 1956, the “Great Smog” hit London, resulting in over 12,000 deaths due to severe air pollution. This historic event led to increased awareness and efforts to enhance indoor air quality globally. Advancements in technology, including thermal imaging, have played a significant role in identifying and resolving indoor air quality issues, ensuring a safer and healthier environment for all.

Unlocking the power of thermal imaging in HVAC system inspections! Discover the secrets to seamlessly incorporating thermal imaging into your inspections. From obtaining the appropriate certifications to investing in high-quality equipment and implementing best practices, this section covers everything you need to know. Prepare to improve efficiency, enhance performance, and thoroughly maintain HVAC systems. Let’s dive in and revolutionise your inspection process!

Training and certification are essential for conducting effective thermal imaging inspections of HVAC systems. Here are some key considerations to ensure proper training and certification in this field:

Investing in quality thermal imaging equipment is essential for conducting effective HVAC system inspections. Here are some key considerations to keep in mind:

By investing in quality thermal imaging equipment, you can enhance the accuracy and efficiency of your HVAC system inspections, leading to improved performance and energy savings.

Conducting effective HVAC system inspections requires adherence to best practices to ensure accuracy and thoroughness. Here are some steps to consider:

In 2008, thermal imaging played a crucial role in detecting a hidden issue during an HVAC system inspection. A small thermal anomaly revealed a faulty electrical connection, preventing a potential fire hazard and ensuring the safety of the building occupants.

Thermal imaging allows inspectors to identify and address issues such as air leakage, missing insulation, and equipment malfunctions that can contribute to inefficiencies in HVAC systems. By detecting heat signatures and temperature variations, thermal imaging provides invaluable insights that enable efficient identification and prevention of problems.

Yes, thermal imaging inspections can help identify areas where heat loss or inefficient systems contribute to wasted energy. By addressing these issues, individuals can optimize their heating and cooling systems, reduce total energy consumption, and ultimately save on utility bills.

Yes, thermal imaging can help identify and address a range of HVAC system issues, including insufficient insulation, air leakage, airflow problems, and malfunctioning parts. By pinpointing these issues early on, thermal imaging allows for prompt repairs or replacements, improving energy efficiency and preventing costly repairs in the long term.

Absolutely. Thermal imaging can be used as a diagnostic tool to proactively identify airflow and duct leaks, poorly sealed areas, and other potential issues before they escalate into significant problems. By implementing preventative measures based on thermal imaging inspections, individuals can optimize HVAC performance and minimize the risk of catastrophic events.

Thermal imaging is particularly valuable in data centers and healthcare spaces where uninterrupted operation, health and safety, and quality control measures are crucial. By detecting temperature variations and anomalies in HVAC systems and equipment, thermal imaging provides data center professionals and healthcare providers with invaluable insights for infrastructure maintenance and efficient identification of potential issues.

Yes, thermal imaging inspections require experienced technicians who are trained in using infrared cameras and interpreting thermal images. Their expertise and understanding of the technology ensure accurate and reliable results, allowing for effective decision-making and improvements in HVAC system efficiency.

Thermal imaging, also known as infrared imaging, is a technology that allows us to visualise and detect temperature variations in objects and environments. It has numerous applications in various industries and sectors. Understanding how thermal imaging works and its potential uses can help demystify this fascinating technology.

What is Thermal Imaging?

Thermal imaging is a technique that uses specialized cameras to capture and display the infrared radiation emitted by objects. It allows us to see and interpret temperature differences, which are represented as varying colors or shades in the images.

How Does Thermal Imaging Work?

Thermal imaging relies on the principles of infrared radiation and its relationship with heat. Infrared technology detects the heat emitted by an object or a person and converts it into an electronic signal. The signal is then processed and translated into a thermal image, which can be viewed on a display.

Types of Thermal Imaging Cameras

There are various types of thermal imaging cameras available, ranging from handheld devices to more advanced, high-resolution cameras. Each type has its own features, specifications, and applications, making them suitable for different environments and purposes.

Applications of Thermal Imaging

Thermal imaging has diverse applications across industries. Some of the key applications include:

Advantages and Limitations of Thermal Imaging

Thermal imaging offers several benefits, such as non-contact measurement, real-time analysis, and the ability to detect hidden problems. However, it also has limitations, including its dependency on temperature differences and its inability to provide detailed information beyond surface-level temperatures.

How to Use Thermal Imaging Cameras

Using thermal imaging cameras requires proper training and understanding of the equipment. This section will cover the basic guidelines and steps for using thermal imaging cameras effectively and safely.

Safety Guidelines for Using Thermal Imaging

To ensure safe and accurate use of thermal imaging cameras, certain safety guidelines must be followed. This section will outline the necessary precautions and best practices to minimize risks and ensure reliable results.

Future Developments in Thermal Imaging Technology

Thermal imaging technology continues to evolve, with ongoing research and development aimed at improving capabilities, enhancing image quality, and making the devices more compact and accessible. This section will explore some exciting future developments in thermal imaging technology.

By gaining a deeper understanding of how thermal imaging works and its various applications, we can appreciate the potential of this technology to revolutionize industries and contribute to new discoveries and advancements.

What is Thermal Imaging?

Thermal imaging is a technology that enables us to visualize and measure the heat emitted by objects and living beings. It utilises infrared radiation to generate images based on temperature differences. By detecting these temperature variations, thermal imaging cameras can provide valuable information in various fields, including electrical inspections, building diagnostics, and search and rescue operations. This technology has proven to be particularly helpful in identifying potential issues before they escalate into significant problems, thereby ensuring safety and efficiency. With thermal imaging, we are able to visualise and analyse the invisible world of heat, making it an invaluable tool in numerous industries.

Thermal imaging works by capturing the heat emitted by objects and converting it into a visual representation. This technology utilises infrared radiation, which is not visible to the human eye but can be detected by thermal cameras. The cameras detect temperature variations and assign different colours to different temperature ranges, allowing users to identify hot and cold spots. This enables professionals in various fields to detect issues such as energy leaks, electrical problems, and even medical conditions. Understanding how thermal imaging works can help users make informed decisions and effectively utilise this powerful technology. Choose the right thermal imaging device for your specific needs with confidence.

Infrared technology is a fundamental component of thermal imaging cameras, which enables the detection and visualization of heat radiation. Infrared radiation refers to the electromagnetic waves emitted by objects due to their temperature. These waves are outside the visible light spectrum, but thermal cameras can detect them. Infrared technology operates by using sensors to measure the intensity of infrared radiation emitted by objects, converting it into temperature data, and creating a thermal image. This technology is extensively used in various industries for applications such as industrial inspections, electrical fault detection, and medical diagnostics. Infrared technology plays a vital role in thermal imaging, allowing us to observe and analyze heat in a non-invasive manner.

True story: Infrared technology played an essential role in rescuing a lost hiker in the wilderness. The hiker had become disoriented and couldn’t find their way back. With the assistance of a search and rescue team equipped with thermal imaging cameras, they were quickly and safely located. The hiker’s body heat stood out against the cooler surroundings, making them easily detectable even in the darkness of night. Infrared technology played a crucial role in saving their life and demonstrating the practical applications of this technology beyond its industrial uses.

Heat and infrared radiation are closely related in thermal imaging. Heat is a form of energy that is produced by the vibration and movement of atoms and molecules. When an object is heated, it emits infrared radiation, which is invisible to the human eye but can be detected by thermal imaging cameras. The amount of infrared radiation emitted by an object is directly proportional to its temperature. Thermal imaging cameras use this relationship to capture and display the infrared radiation emitted by objects, allowing us to visualize and analyze temperature differences. Understanding this relationship is crucial in interpreting thermal images and identifying potential issues or anomalies.

Thermal imaging cameras are available in various types, each designed for specific applications. Here is a breakdown of the different types:

| Types | Description |

|---|---|

| Handheld Cameras | These portable and easy-to-use cameras are perfect for inspections and troubleshooting in small spaces. |

| Fixed-Mount Cameras | Typically used for continuous monitoring, these cameras are installed in a fixed position to capture thermal images over a long period of time. |

| Pan-Tilt-Zoom Cameras | These cameras offer flexibility by allowing users to remotely control the direction and zoom of the camera, making them ideal for surveillance and security purposes. |

| Smartphone Thermal Cameras | These compact cameras can be attached to smartphones, enabling users to capture thermal images using their mobile devices. |

A firefighter saved a young child’s life using a handheld thermal imaging camera. He located the child trapped in a burning building by detecting his body heat, leading to a successful rescue. The advanced technology of thermal imaging cameras continues to make a significant impact in various industries.

Thermal imaging has a wide range of applications in different industries, providing valuable insights and enhancing safety. Here are some key applications of thermal imaging:

Building Inspections: Thermal imaging can detect energy leaks, moisture issues, and electrical faults.

Industrial Maintenance: It helps identify overheating equipment, potential failures, and faulty electrical connections.

Firefighting: Thermal cameras enable firefighters to locate hotspots and people in smoke-filled environments.

Medical Diagnosis: Thermal imaging can assist in diagnosing conditions such as inflammation, circulation problems, and breast abnormalities.

Security: It plays a crucial role in surveillance by detecting intruders in low-light conditions.

By utilizing thermal imaging technology, these applications help improve efficiency, safety, and decision-making in various fields.

Industrial inspections are vital for ensuring the safety and efficiency of industrial processes. Thermal imaging cameras are commonly used in these inspections to detect anomalies and potential issues. Here is a table summarising the benefits of using thermal imaging cameras for industrial inspections:

| Benefits of Thermal Imaging Cameras for Industrial Inspections |

|---|

| Early detection of equipment malfunction |

| Identification of energy inefficiencies |

| Non-destructive testing and troubleshooting |

| Improved safety for personnel |

| Reduction in downtime and maintenance costs |

By utilising thermal imaging cameras, companies can proactively identify and address problems before they lead to major breakdowns or accidents. Investing in regular industrial inspections can result in significant cost savings and improved operational performance.

Electrical and mechanical fault detection using thermal imaging cameras involves a systematic approach to identify potential issues. Here are the steps to follow:

Fun Fact: Thermal imaging can detect electrical faults in low voltage components even before they start to smoke or catch fire, helping prevent hazardous situations.

Building Insulation and Energy Audits are essential for improving energy efficiency and reducing costs. When conducting building insulation and energy audits, several factors should be taken into account:

To further enhance energy efficiency, the utilization of smart technologies like programmable thermostats or energy management systems should be considered. Regular maintenance and monitoring are key to optimizing energy consumption and reducing environmental impact.

Medical Diagnostics in thermal imaging involve using the technology to detect and diagnose various health conditions. It allows for non-invasive imaging of the body, providing valuable insights to healthcare professionals.

| Application | Description |

| Inflammation Detection | Thermal imaging can identify areas of inflammation in the body, aiding in the diagnosis of conditions such as arthritis and tendonitis. |

| Neuromuscular Disorders | The technology can detect abnormalities in the nervous and muscular systems, assisting in the diagnosis of conditions like nerve damage and muscular dystrophy. |

| Vascular Issues | Thermal imaging can identify circulation problems and vascular disorders by detecting temperature differences in the affected areas. |

| Screening for Breast Cancer | Thermal imaging can be used as an additional tool for breast cancer screening, particularly in women with dense breast tissue. |

Using thermal imaging can provide several benefits in various industries and applications. Here are some of the advantages of thermal imaging:

With these benefits, it’s no wonder that thermal imaging has become an invaluable tool in various fields, from industrial inspections to medical diagnostics.

True History Fact: Thermal imaging was first used in World War II by the military to detect enemy personnel and vehicles at night or in difficult weather conditions. This early application paved the way for the development of modern thermal imaging technology.

Thermal imaging has several advantages, but it also has a few limitations that should be considered:

True story: A firefighter once used a thermal imaging camera to locate a trapped individual in a smoke-filled building. Despite these limitations, the camera was able to identify the person’s body heat signature, leading to a successful rescue operation.

Remember to regularly update your knowledge on thermal imaging technology and explore new applications to maximize the benefits of using thermal imaging cameras.

Future Developments in Thermal Imaging Technology

True story: In a recent incident, a thermal imaging camera helped firefighters locate a trapped individual in a smoke-filled building. The camera’s ability to detect heat signatures enabled the firefighters to quickly locate the person and rescue them, highlighting the life-saving potential of future developments in thermal imaging technology.

Thermal cameras work by detecting and converting infrared energy into electronic images, using a thermal sensor and processing electronics. They do not detect visible light but focus on heat or thermal energy. The cameras can detect tiny differences in heat and display them as shades of grey or with different color palettes, creating a visual image.

When choosing a thermal camera, important specifications to consider include resolution, range, field of view, focus, thermal sensitivity, and spectral range. These specifications determine the camera’s ability to detect heat differences, capture detailed images, and provide accurate temperature readings.

Yes, thermal cameras can work in complete darkness. They produce images and videos from heat energy, not visible light. They can detect infrared radiation emitted by all objects, regardless of lighting conditions, making them reliable in dark environments.

Thermal imaging technology plays a crucial role in the development of ADAS and AV. Infrared radiation, which is longer than visible light, can be detected by infrared detectors and converted into an electronic signal to generate thermal images. Thermal cameras mounted on vehicles can detect heat signatures, identify hot spots, and assist in threat detection, enhancing road safety.

Thermal cameras have a wide range of applications in industrial facilities, including predictive maintenance, electrical facilities inspections, and monitoring temperature-sensitive processes. They can detect anomalies such as overheating equipment or components, helping to prevent breakdowns and improve safety in industrial environments.

No, thermal cameras cannot see through objects. However, they can see through thin materials like plastic, fog, smoke, foliage, dust, rain, sand, and snow. They rely on the infrared energy emitted by objects and can accurately map heat distribution, providing valuable insights in various scenarios.

Thermal imaging plays a vital role in electrical inspections as it identifies potential issues before they escalate into serious problems. It enables technicians to identify overheating components, loose connections, and faulty wiring, thereby preventing electrical fires and equipment malfunctions. By capturing and analysing heat signatures, thermal cameras provide valuable data that aids in making informed decisions for maintenance and repair. The primary purpose of thermal imaging in electrical inspections is to enhance safety, improve efficiency, and minimise downtime. Studies have even indicated that thermal imaging can reduce the occurrence of electrical failures by up to 50%.

Thermal imaging is a technology that captures and produces images based on the heat emitted by objects. It is used to detect variations in temperature and identify potential issues in electrical systems. By detecting abnormal heat patterns, thermal imaging allows for early detection of overheating components, loose connections, or faulty wiring. This helps prevent electrical fires and costly damages. Thermal imaging works by using infrared radiation to convert temperature differences into visual images. It enables inspectors to see areas of concern that are not visible to the naked eye. With proper equipment and training, thermal imaging is a valuable tool in electrical inspections for ensuring safety and identifying potential electrical issues.

Thermal imaging works by detecting and measuring the infrared radiation emitted by objects. It uses a specialised camera that can detect these heat signatures and convert them into visible images. This process is based on the principle that all objects emit some level of thermal energy, even at temperatures below freezing. The camera captures the heat patterns and displays them as a colour spectrum, with different colours representing different temperatures. This allows electrical inspectors to identify hotspots, anomalies, and potential issues in electrical systems. By understanding how thermal imaging works, inspectors can effectively use this technology to identify problems early and prevent electrical failures.

Thermal imaging is important in electrical inspections because it allows for the identification of potential problems that may not be visible to the naked eye. Here are some reasons why thermal imaging is important in electrical inspections:

Thermal imaging in electrical inspections offers several advantages, enhancing safety and efficiency, and enabling the identification of electrical issues and faults.

Incorporating thermal imaging in electrical inspections has revolutionised the industry, making it easier to identify and resolve electrical problems before they escalate. Its ability to detect hidden issues and prevent accidents has made it an invaluable tool in maintaining electrical safety.

Historically, thermal imaging was first developed for military purposes during World War II to detect enemy threats and has since evolved into a critical technology used in various fields, including electrical inspections. Today, it is widely recognised as a reliable method for ensuring electrical system integrity and safety.

While thermal imaging is a valuable tool for electrical inspections, it does have certain limitations. It is important to be aware of these limitations when using thermal imaging to ensure accurate and reliable results.

Despite these limitations, thermal imaging remains a valuable tool for electrical inspections, providing insights into potential issues and promoting safety.

Thermal imaging is employed in electrical inspections to detect potential issues that are not visible to the naked eye. It is utilised to identify electrical hotspots, such as overheating wires or components, which can indicate faults or inefficiencies. By capturing temperature variations in electrical systems, thermal imaging helps to pinpoint areas of concern that require immediate attention. This non-invasive technology enables inspectors to identify and mitigate potential hazards before they result in equipment failure, power outages, or fires. The use of thermal imaging during electrical inspections ensures the safety and reliability of electrical systems.

When conducting a thermal imaging inspection, there are several key steps involved:

In electrical inspections, thermal imaging has a range of common applications that assist in the identification of potential issues and the maintenance of safety.

1. Enclosing faulty connections: Thermal imaging can detect loose or corroded electrical connections that may result in overheating and pose a fire risk.

2. Spotting overloaded circuits: By capturing temperature variations, thermal imaging can identify circuits that are carrying excessive loads, allowing for timely adjustments.

3. Locating hidden faults: It enables technicians to identify hidden faults within electrical systems, such as faulty insulation or damaged components, preventing further damage.

4. Inspecting switchgear and transformers: Thermal imaging is useful for inspecting high-voltage equipment, identifying abnormal temperature patterns that may indicate potential failures.

Pro-tip: Regular thermal imaging inspections can help identify potential electrical issues before they escalate, ensuring the safety and reliability of electrical systems.

Discover the amazing benefits of using thermal imaging for electrical inspections. Uncover the potential for improved safety, prevention of electrical fires, and preservation of both lives and property. Experience enhanced efficiency and productivity as potential issues are quickly identified. By embracing thermal imaging, electrical inspections become a valuable tool in identifying and addressing faults, ensuring the reliability and longevity of electrical systems. Stay ahead of the game with this innovative technology that is revolutionizing the field of electrical inspections.

To enhance safety and prevent electrical fires, it is crucial to use thermal imaging in electrical inspections. This technology enables the detection of hotspots, identifying potential fire hazards before they escalate. Here are the key steps involved in conducting a successful thermal imaging inspection:

Ensure proper equipment and training for accurate readings.

Conduct inspections regularly to identify potential issues.

Inspect electrical connections, circuits, and equipment for abnormal heating.

Capture thermal images of electrical components to identify temperature anomalies.

Analyze the images to determine if there are any areas of concern.

Take immediate action to address any detected abnormalities, such as identifying loose connections, overloaded circuits, or damaged equipment.

Regularly monitor and reassess electrical systems to maintain a safe environment.

By following these steps and utilizing thermal imaging technology, the safety of electrical systems can be significantly enhanced, preventing potential electrical fires.

Improved efficiency and productivity are important benefits of using thermal imaging in electrical inspections. Thermal imaging enhances efficiency and productivity in several ways:

To maximize efficiency and productivity during thermal imaging inspections, consider the following suggestions:

Identification of electrical issues and faults is a crucial aspect of electrical inspections. The process involves several key steps:

Visual inspection: A thorough visual examination of electrical components is conducted to identify any visible signs of damage or wear.

Infrared scanning: Thermal imaging cameras are used to detect abnormal heat patterns, which can indicate electrical faults such as loose connections or overloaded circuits.

Data analysis: The captured thermal images are analysed and compared to reference standards to identify any anomalies or areas of concern.

Proper documentation: The findings, along with the location and severity of each identified issue or fault, are documented.

By following these steps, electrical professionals can effectively identify and address potential hazards, ensuring the safety and proper functioning of electrical systems.

When conducting a thermal imaging inspection, it is important to consider certain factors that are crucial to its success. This section will delve into the key aspects of this process, including the importance of using appropriate equipment and receiving adequate training, as well as the significance of understanding thermography and interpreting images. So, let’s embark on this journey to explore the intricacies of thermal imaging inspections!

Proper equipment and training are essential for conducting successful thermal imaging inspections in electrical systems. Here are the key steps to ensure the effective use of thermal imaging tools:

By following these steps and maintaining proper equipment and training, electrical inspections can be conducted effectively, leading to enhanced safety, improved efficiency, and timely identification of electrical issues.