20+ Years Experience

Specialist Thermal Imaging

Enquire Today For A Free No Obligation Quote

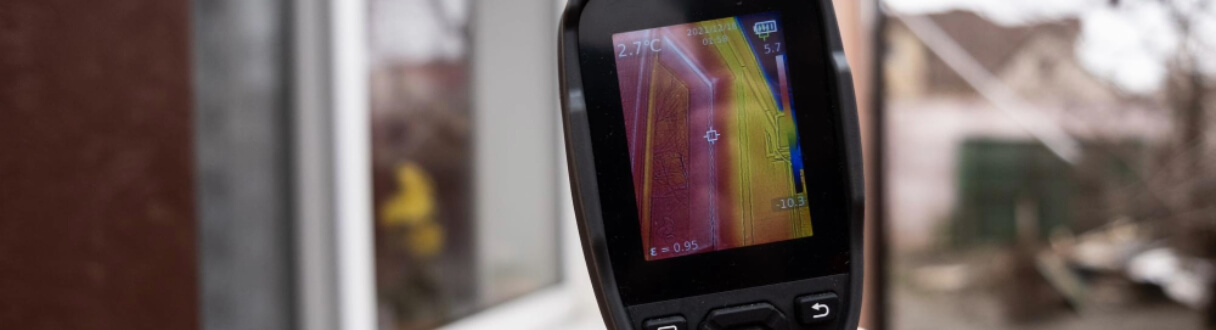

Choosing the right thermal imaging equipment is of paramount importance when it comes to accurate and effective thermal imaging applications. Thermal imaging technology is widely used in various industries such as electrical, mechanical, building inspection, and security. The right equipment ensures that you can capture clear and precise thermal images, enabling you to identify potential issues and make informed decisions. When choosing thermal imaging equipment, there are several vital factors to consider.

Resolution and image quality are crucial in thermal imaging. Resolution determines the level of detail and clarity in the thermal images. A higher resolution allows for better image quality, making it easier to interpret and analyze the temperature differences. Likewise, temperature range is another essential factor to consider. The range determines the minimum and maximum temperatures that the camera can accurately measure. Selecting a camera with an appropriate temperature range ensures that it can capture the desired temperature variations.

Sensitivity and noise are critical considerations. Sensitivity refers to the camera’s ability to detect small temperature differences. A more sensitive camera provides more accurate results. The presence of noise can affect the clarity and accuracy of the thermal images, so it’s important to choose equipment with low noise levels.

Field of view and focus are important for capturing the desired area effectively. Field of view determines the width and height of the area covered in the image. A wider field of view allows for capturing larger areas at once. Focus ensures that the thermal imaging camera can produce sharp and clear images. It is crucial when inspecting smaller details or specific objects.

Considering the durability and portability of the equipment is also essential. Thermal imaging equipment should be able to withstand challenging environments and conditions. Portability allows for convenience and flexibility in various applications.

Lastly, the user interface and additional features should be considered. An intuitive and user-friendly interface enhances the user experience and makes operating the equipment more efficient. Additional features such as Wi-Fi connectivity, image storage, and analysis software can provide added convenience and functionality.

By carefully considering these factors, you can select the right thermal imaging equipment that suits your specific needs, ensuring accurate and reliable thermal imaging results.

Choosing the right thermal imaging equipment is important because it ensures that you have the most suitable equipment for your specific needs. In this section, we will explore the factors that need to be considered in order to make the right choice. So, let’s dive into the world of thermal imaging and its significance in various industries.

Selecting the right thermal imaging equipment requires considering several factors to ensure accurate and reliable results.

Resolution and image quality are important factors to consider when choosing thermal imaging equipment. These factors determine the clarity and accuracy of the images produced by the device. Higher resolution cameras capture more detailed images, allowing for better analysis and detection of temperature variations. It is important to select a camera with a resolution that matches the requirements of your application. Image quality is influenced by factors such as thermal sensitivity, temperature range, and noise reduction capabilities. Evaluating these features will help you choose a thermal imaging device that provides high-quality, reliable images for your specific needs.

| Factors to Consider | Importance |

| Resolution | High |

| Thermal Sensitivity | High |

| Temperature Range | Medium |

| Noise Reduction | Medium |

Resolution in thermal imaging refers to the number of pixels or details that can be captured in an image. It determines the level of clarity and sharpness in the thermal image. Higher resolution cameras can capture more precise details and provide better image quality, allowing for more accurate thermal analysis. The resolution is measured in terms of pixels, with higher numbers indicating better image quality. It is important to consider resolution when choosing thermal imaging equipment as it directly impacts the effectiveness and accuracy of the thermal inspections. Higher resolution cameras are recommended for applications that require detailed thermal analysis, such as electrical or mechanical inspections.

The accuracy of thermal imaging is directly affected by the image quality of the equipment. Cameras with higher resolution can provide clearer and more detailed images, enabling better analysis and detection of temperature variations. Conversely, lower quality images may lead to missed or misinterpreted information. Image noise can also impact accuracy by obscuring important details and making it difficult to distinguish temperature variations. Therefore, when selecting thermal imaging equipment, it is crucial to consider image quality and ensure that it meets the requirements of your specific application.

Fun Fact: Did you know that some thermal imaging cameras can detect temperature differences as small as 0.02 degrees Celsius?

The temperature range is a crucial factor to consider when choosing thermal imaging equipment. Here are some points to keep in mind:

In 1817, Sir William Herschel discovered infrared radiation while conducting experiments with temperature measurements. His discovery laid the foundation for the development of thermal imaging technology.

The temperature range is a crucial factor to consider when choosing thermal imaging equipment. It refers to the minimum and maximum temperatures that the camera can accurately detect. Understanding the temperature range is essential as it determines the device’s ability to capture thermal variations and identify hotspots or anomalies. For example, if you are working in an industrial setting, you need a camera with a wide temperature range to detect temperature fluctuations in machinery or processes. Conversely, if you are conducting building inspections, a smaller temperature range may be sufficient. Choosing a thermal imaging device with an appropriate temperature range ensures accurate and reliable thermal analysis.

The development of thermal imaging dates back to the early 20th century when scientists first discovered that objects emit infrared radiation. Since then, thermal imaging technology has advanced significantly, with temperature range being one of the key areas of improvement. Early thermal imaging cameras had limited temperature ranges, making them less effective in certain applications. With advancements in sensor technology and image processing algorithms, modern thermal imaging equipment now offers wider temperature ranges, allowing for more precise and detailed thermal analysis. This evolution has revolutionised industries such as building inspections, electrical maintenance, and medical diagnostics, enabling professionals to detect and address issues with greater accuracy and efficiency.

Temperature range is an important factor to consider when selecting thermal imaging equipment. The temperature range refers to the minimum and maximum temperatures that the camera can accurately detect. This is crucial because different applications require different temperature ranges. For instance, electrical inspections may require a wider temperature range in order to accurately identify overheating components. On the other hand, building inspections may require a narrower temperature range for better accuracy in detecting heat loss or air leaks. Therefore, it is essential to understand the temperature range of the thermal imaging equipment to ensure that it is suitable for the intended application.

Pro-tip: Before purchasing thermal imaging equipment, carefully evaluate the temperature range requirements specific to your application to ensure optimal performance.

Sensitivity and noise are important factors to consider when selecting thermal imaging equipment. The sensitivity of a device determines its ability to detect even the smallest temperature differences, while lower noise levels ensure clearer and more accurate thermal images. To compare different models, you should assess their Noise Equivalent Temperature Difference (NETD) values. It is advisable to look for lower NETD values as they indicate higher sensitivity and lower noise. For instance, the FLIR E75 has an impressive NETD value of 0.03°C, which makes it perfect for capturing even the most subtle temperature variations. Investing in a thermal imaging camera with high sensitivity and low noise guarantees precise and reliable thermal measurements.

In the early days of thermal imaging, sensitivity and noise posed significant challenges. However, advancements in technology have resulted in the development of highly sensitive and low-noise thermal imaging equipment. These improvements have revolutionized various industries, including security, building inspections, and medical diagnostics. Today, professionals can confidently rely on thermal imaging devices with exceptional sensitivity and minimal noise levels to detect and analyze temperature patterns with unmatched precision. This has greatly enhanced efficiency, safety, and decision-making capabilities across diverse fields.

In thermal imaging, sensitivity refers to the smallest temperature difference that the camera can detect. It is an important factor to consider when choosing thermal imaging equipment. Sensitivity determines the level of detail and accuracy in the thermal images produced. Higher sensitivity allows the camera to detect even subtle temperature variations, resulting in more precise measurements. This is particularly crucial in applications such as electrical inspections, building diagnostics, and medical screenings. By understanding what sensitivity represents, users can select the most suitable thermal imaging equipment for their specific needs.

Noise can have a significant impact on the effectiveness of thermal imaging. Excessive noise in the image can make it challenging to interpret thermal patterns or identify anomalies accurately. High levels of noise can distort temperature readings and obscure important details, reducing the overall accuracy and reliability of the thermal imaging equipment. It can also affect the image quality, making it more difficult to distinguish between different heat signatures. Therefore, it is essential to choose thermal imaging equipment with low noise levels to ensure clear and precise thermal images for more accurate analysis and decision-making.

When considering thermal imaging equipment, it is crucial to take into account the field of view and focus. These factors play a significant role in ensuring accurate and effective imaging results.

The field of view in thermal imaging refers to the area that can be seen and captured by the thermal camera. It determines the extent of the image that can be analysed for temperature variations. A wider field of view allows for capturing a larger area at once, which is beneficial for monitoring large spaces or conducting surveys. On the other hand, a narrower field of view provides more detail and accuracy when focusing on smaller targets. Understanding the field of view is crucial as it determines the level of detail and coverage that can be achieved in thermal imaging applications.

Having the right focus in thermal imaging is essential for accurate and reliable results. It ensures that the intended target is properly captured and analysed, providing valuable insights.

Factors to consider in focus include the Field of View (FOV), which determines the area being observed, and the resolution, which affects the clarity and detail of the images.

Without proper focus, thermal imaging may result in inaccurate temperature measurements and blurry images, leading to erroneous analysis and decision-making.

Pro-tip: Always take the time to adjust and fine-tune the focus of your thermal imaging equipment for optimal results. This will enhance the accuracy and effectiveness of your thermal imaging applications.

Durability and portability are important factors to consider when selecting thermal imaging equipment. Here are some key points to remember:

| Build quality: | Look for equipment made from robust materials that can withstand harsh conditions. |

| Water and dust resistance: | Choose devices with an IP rating to ensure protection against water and dust damage. |

| Impact resistance: | Find equipment with features that can withstand accidental drops. |

| Size and weight: | Consider the portability of the device, especially if you need to carry it for long periods. |

| Battery life: | Longer battery life ensures uninterrupted usage in the field. |

Give priority to thermal imaging equipment that combines durability and portability to meet your specific requirements. Some recommended options include the Fluke Ti450 Pro Infrared Camera and the Seek Thermal Compact Pro.

Durability is a crucial factor to consider when it comes to thermal imaging equipment. There are several reasons why durability is essential for thermal imaging equipment:

When considering portability in thermal imaging equipment, it is important to take several factors into account. These factors include the weight of the device, its size, and the availability of carrying options such as straps or cases. Additionally, it is crucial to consider the battery life and power source to ensure uninterrupted usage in the field. The level of ruggedness and durability of the equipment is also essential, especially when it needs to withstand harsh conditions. Furthermore, the ease of operation and a user-friendly interface are important for efficient and effective use. Portability is key for professionals who need to move around easily during inspections or surveys.

Fact: Compact thermal imaging cameras can weigh as little as 0.5 pounds, which makes them highly portable and suitable for on-the-go applications.

When selecting thermal imaging equipment, it is important to consider the user interface and features to ensure optimal performance and ease of use.

Fact: Did you know that thermal imaging technology was first developed for military purposes during World War II?

When selecting thermal imaging equipment, it is crucial to consider the user interface elements that promote ease of use and accurate results. These elements include:

1. Display: A clear and user-friendly display allows users to easily interpret thermal images and adjust settings.

2. Controls: Intuitive controls enable users to navigate menus, modify settings, and capture images effortlessly.

3. Temperature measurement tools: User-friendly temperature measurement tools, such as spot meters or temperature scales, enhance accuracy and precision.

4. Image analysis software: Advanced image analysis software with user-friendly interfaces enables users to effectively analyze and interpret thermal data.

5. Data storage and sharing: Seamless data storage and sharing capabilities allow for efficient documentation and collaboration.

Considering these essential user interface elements ensures a smooth and efficient thermal imaging experience.

When considering the right thermal imaging equipment, there are several additional features to take into account that can enhance its effectiveness and usability.

Taking these additional features into consideration can greatly enhance your thermal imaging experience and provide you with the necessary functionality for your specific applications.

The important qualities to consider when choosing a thermal imaging camera are the temperature range, resolution, accuracy and repeatability, durability, and image fusion capabilities.

The temperature range determines the likely temperature at which images will be captured. It is important to choose a camera that can detect the temperature range relevant to your application.

Resolution determines the clarity of the thermal images and the ability to detect smaller temperature differences. Higher resolution is essential for professional purposes like electrical inspections.

Accuracy and repeatability are important as thermal imaging cameras are often used to measure temperature differences. Choosing a camera with a high level of accuracy, typically ±2% or better, ensures reliable temperature measurements.

Durability is important, especially for applications exposed to outdoor elements or rugged industrial environments. Choosing a durable camera ensures it can withstand these conditions and perform reliably over time.

Yes, there are thermal imaging cameras with image fusion capabilities. These cameras can clearly highlight the differences between thermal and visible light images, making analysis easier in certain applications.

We Aim To Reply To All Enquiries With-in 24-Hours