20+ Years Experience

Specialist Thermal Imaging

Enquire Today For A Free No Obligation Quote

Thermal imaging plays a crucial role in the field of building construction by aiding in the identification of structural issues. The technique utilizes infrared technology to capture and visualize the heat signatures emitted by different objects, allowing for the detection of underlying problems that may not be visible to the naked eye. Thermal imaging is widely employed due to its accuracy and efficiency in assessing building components and systems. Understanding its principles and applications is essential for professionals in the construction industry.

To comprehend thermal imaging in building construction, it is necessary to explore its definition, working mechanism, and why it is commonly utilized in this field. focusing on the identification of structural issues is vital, as it highlights specific areas where thermal imaging proves to be a valuable tool. These include detecting heat loss and energy inefficiency, locating moisture and water intrusion, inspecting electrical systems, finding HVAC system problems, and identifying insulation deficiencies. By addressing these issues promptly, building professionals can ensure the safety, durability, and energy efficiency of structures.

However, while thermal imaging offers numerous benefits for building construction, it is important to be aware of its limitations. Familiarizing oneself with the advantages and limitations of thermal imaging can help professionals effectively employ this technology and interpret its results accurately. Furthermore, understanding the types of thermal imaging cameras available and the additional equipment required for precise thermal imaging is essential for conducting thorough inspections. Lastly, training and certification programs are available to equip thermal imaging professionals with the necessary skills and knowledge to utilize this technology effectively and efficiently.

By delving into the intricacies of thermal imaging in building construction, professionals can harness its potential to identify structural issues, improve energy efficiency, and enhance the overall quality of construction projects.

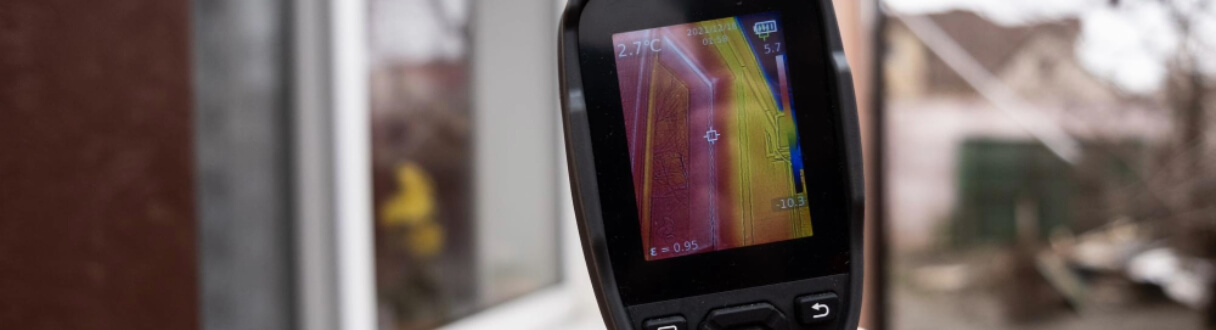

Thermal Imaging is a non-contact technology that is used to detect and visualize variations in surface temperature. It works by capturing the infrared radiation emitted by objects and converting it into a visible image. This technology is particularly useful in building construction as it can be used to identify structural issues such as insulation gaps, water leaks, and electrical faults. Thermal imaging cameras are able to detect these problems by highlighting temperature differences that are not visible to the naked eye. By identifying these issues early on, necessary repairs can be made, saving both time and money. In fact, thermal imaging can even identify hidden water leaks behind walls without the need for destructive testing.

Thermal imaging works by detecting and capturing the infrared radiation emitted by objects. This radiation is converted into a thermographic image that shows variations in temperature. Thermal imaging cameras use specialised sensors to detect and measure the radiation, which is then displayed as different colours or shades on the image. This technology allows for the identification of temperature differences and patterns, helping to locate issues such as heat loss, moisture intrusion, electrical problems, and insulation deficiencies. A pro-tip for effective thermal imaging is to ensure a temperature contrast between the object of interest and the surrounding environment, as this enhances the accuracy of the image.

Thermal imaging is extensively used in building construction for various reasons. It helps to identify structural issues such as heat loss and energy inefficiency, moisture and water intrusion, electrical system defects, HVAC system problems, and insulation deficiencies. By detecting these issues early on, builders can take corrective measures to enhance energy efficiency, prevent damage, and ensure occupant comfort. Thermal imaging is a non-invasive method that allows for quick and accurate diagnostics, saving time and money. It can also help identify potential safety hazards, such as overheating electrical components. Therefore, thermal imaging is a valuable tool that aids in building construction quality control and maintenance.

As a historical example, thermal imaging was first used in building construction by NASA during the Apollo program in 1965. Engineers used thermal imaging cameras to detect heat leaks and insulation deficiencies in the spacecraft. This breakthrough technology not only improved the safety and performance of the spacecraft but also paved the way for its widespread use in modern building construction.

Using thermal imaging technology in building construction enables efficient identification of structural issues. This section explores the practical applications of thermal imaging, such as the detection of heat loss and energy inefficiency, the location of moisture and water intrusion, the inspection of electrical systems, the identification of HVAC system problems, and the recognition of insulation deficiencies. Thermal imaging helps builders and inspectors quickly identify and address potential issues, ensuring the structural integrity and energy efficiency of buildings.

Detecting heat loss and energy inefficiency is a crucial aspect of thermal imaging in building construction. Thermal imaging cameras are used by professionals to identify areas where insulation is inadequate or compromised, resulting in energy loss. These cameras detect temperature differences and generate thermograms, which are visual images that highlight areas of heat leakage. Thermal imaging is useful for detecting air leaks, poor insulation, and gaps in windows or doors, allowing for prompt repairs and energy-saving measures. It enables building owners to make informed decisions about energy-efficient upgrades and ultimately reduce energy consumption and utility costs.

To locate moisture and water intrusion in building construction, thermal imaging can be a valuable tool. It allows for the detection of hidden moisture sources that may lead to structural damage or mould growth. Here are the steps involved in using thermal imaging for locating moisture and water intrusion:

By following these steps, thermal imaging can effectively identify moisture and water intrusion in building construction, allowing for timely repairs and maintenance.

To further enhance electrical system inspections, consider these suggestions:

– Regularly perform inspections to identify any potential issues before they escalate.

– Provide proper training to the personnel conducting the inspections to ensure accurate interpretation of thermal images.

– Follow applicable safety standards and regulations to maintain a safe working environment.

When it comes to identifying HVAC system problems using thermal imaging in building construction, there are several steps to consider:

Inspect ductwork: Check for leaks or gaps in the ducts that can lead to energy inefficiency.

Scan airflow: Detect any blockages or obstructions in the HVAC system that may hinder proper airflow.

Analyze temperature variations: Identify any hotspots or cold areas that may indicate problems with the HVAC system.

Check insulation: Assess the insulation around the HVAC system to ensure it is properly installed and not causing any energy losses.

Monitor electrical connections: Look for any overheating or loose connections within the HVAC system, which can lead to electrical issues.

By following these steps, thermal imaging can be a valuable tool in identifying HVAC system problems in building construction.

Identifying insulation deficiencies is crucial in buildings for energy efficiency and comfort. To effectively identify insulation issues, follow these steps:

Understanding insulation deficiencies can help homeowners and building professionals make informed decisions to enhance energy efficiency and reduce heating and cooling costs.

In the 1940s, with the development of modern insulation materials, buildings started to see significant improvements in energy efficiency. By identifying insulation deficiencies, architects and engineers were able to optimize building designs, leading to better thermal comfort and reduced energy consumption. Today, technological advancements in thermal imaging and energy auditing have made it easier than ever to identify and address insulation issues in buildings.

True story: A construction company used thermal imaging to identify an insulation problem in a new building. By addressing the issue early on, they prevented energy loss and saved on future repairs.

Using thermal imaging in building construction offers several advantages, making it a valuable tool for professionals in the industry. These advantages include:

These advantages make thermal imaging an essential technique for effectively assessing and maintaining the structural integrity of buildings.

Thermal imaging in building construction has several limitations that should be taken into consideration. These limitations include:

Considering these limitations, it is important to use thermal imaging in conjunction with other inspection methods to ensure a comprehensive assessment of building structures.

Thermal imaging technology has revolutionised the field of building construction, enabling professionals to identify and address structural issues more effectively. This section explores the world of thermal imaging tools and equipment, uncovering the various types of thermal imaging cameras available and the additional equipment crucial for ensuring accurate thermal imaging results. Explore how these cutting-edge technologies can enhance the accuracy and efficiency of detecting structural anomalies in construction projects.

“`

Types of Thermal Imaging Cameras

There are various types of thermal imaging cameras available, each with its own features and specifications.

| Camera Type | Description |

| Uncooled cameras | These cameras are lightweight, portable, and cost-effective. They use microbolometer technology to detect thermal energy. |

| Cooled cameras | These cameras use a more advanced technology, where the detectors are cooled to very low temperatures. They offer higher sensitivity and better image quality. |

| Fixed cameras | These cameras are permanently installed in specific locations for continuous monitoring. They are commonly used for security and surveillance purposes. |

| Handheld cameras | These cameras are lightweight and portable, making them suitable for on-the-go inspections and troubleshooting. |

| Mobile cameras | These cameras are mounted on vehicles or drones, allowing for aerial thermal imaging and wide-area surveillance. |

Additional equipment is required to ensure accurate thermal imaging in building construction. This equipment enhances inspections and improves the precision of temperature calculations. The following tools may be used:

By utilising these additional tools, thermal imaging professionals can enhance their accuracy and effectiveness in identifying structural issues in building construction.

Training and certification are vital for thermal imaging professionals to ensure they have the necessary knowledge and skills. When choosing training and certification programs, the following aspects should be considered:

Thermal imaging, also known as infrared thermography, is a non-destructive investigation technique used in building construction. It allows for the analysis of objects without causing damage and helps visualize and quantify temperature variations across surfaces.

Thermal imaging can detect structural deficiencies, moisture, thermal bridges, cracks, and areas of heat loss or air leakage in buildings. It is a useful tool for identifying construction defects and shoddy construction work that may impact energy efficiency and insulation efficacy.

The Workswell WIRIS thermal camera system offers several advantages, including manual calibration for precise surface temperature measurement, the ability to change emissivity and reflected temperature mid-flight, and the production of traditional photos alongside thermal images for easier identification of construction components. It also stores all radiometric data, allowing for the production of a measurement report that can be used in claims.

The ideal conditions for thermographic work are a temperature difference of at least 10°C between the interior and exterior of a building. Thermographic measurements cannot be taken during heavy rain or snow.

Drones are now being used for thermographic building inspections, especially for tall structures or houses with difficult-to-access roofs. Drones can safely and efficiently map the entire exterior of a building, allowing for comprehensive thermographic inspections.

Alongside thermal imaging, other non-destructive techniques used in building conservation include 3D laser scanning, microwave moisture analysis, and heat flow sensors. These techniques help analyze and diagnose the condition and behavior of buildings without causing damage.

We Aim To Reply To All Enquiries With-in 24-Hours